Aerospace Heat Treating Solutions

Aerospace part heat treating specifications can be tough to meet. CEC can make it easy.

Meet Spec the First Time, Every Time.

Close enough isn’t enough when it comes to critical aerospace components. CEC will work with you to create a heat treatment system that hits time and temperature targets precisely, from the first load to the last. And for every load in-between, CEC will support you with uncompromising standards and world-class service.

What We Build for Aerospace

- Drop-Bottom and Vertical Drop Bottom – fastest quench for thin skins, spars, and large tanks; engineered for repeatable immersion times

- Roller-Hearth T6/T7 Lines – high throughput castings/forgings with air, water, or oil quench

- Atmosphere Retort (Brazing) – clean joints and tight temperature control for engine, APU, and ducting assemblies

- Titanium Heat Treat – creep-strength control and microstructure stability

- Batch/Continuous Age Ovens – uniformity-first design for large and mixed loads

- Tundish Preheat – integrated to the line

The CEC Advantage

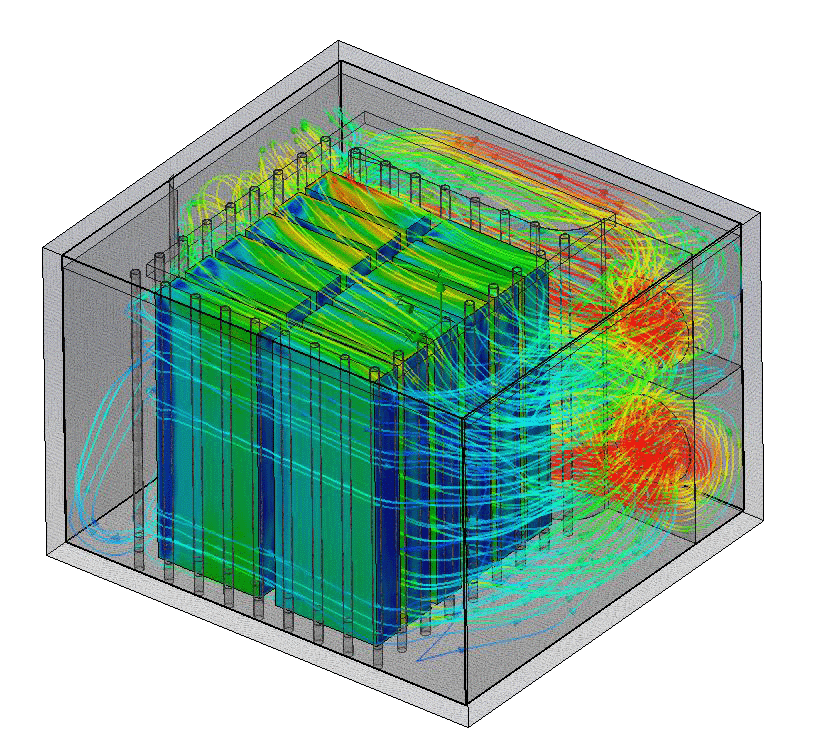

- Uniformity by design – We use CFD to simulate airflow, nozzle angles, recirculation paths/flows, and your worst-case load geometry, so hot/cold spots are engineered out before the first TUS.

- Testing & standards — Designed to meet or exceed AMS2750 and AMS2770, with NADCAP/CQI-9–ready data: batch reports, e-signatures, secure retention.

- Built with you — Joint design reviews with your engineering, production, and maintenance teams to ensure intuitive operation, PM access, and documentation that hit spec and accelerate qualification.

- Lifecycle support — aftermarket parts, service, and upgrades—even on non-CEC furnaces

Typical Aerospace Applications

- Wing & fuselage: skins, spars, bulkheads (solution + quench + age)

- Rocket engine components — injectors, jackets, nozzles (brazing/age; retort atmosphere control)

- Landing gear & seat castings: T6/T7 with progressive or immersion quench

- Turbine section: brazed subassemblies, retort cycles

- Tubes, bars, extrusions: horizontal lines with right-angle transfer and progressive quench; vertical solutions for low-distortion T6 on 6xxx alloys

- Extrusions & long products — 2xxx/6xxx/7xxx profiles for airframe (solution + quench, age; progressive quench)

- Machined plate & forgings — frames, ribs, brackets (solution + quench, age; distortion control)

- Fasteners & hardware — pins, bolts, inserts (age hardening / PH stainless cycles)

- Engine hot-section — blades, vanes, rings (age hardening; vacuum/retort brazing of honeycomb and seals)

- APU & ECS ducting — thin-wall assemblies (brazing/anneal; tight uniformity)

Controls and Data Integrity

SAT/TUS planners, automatic scheduling, and pass/fail logging (AMS2750)

Secure historian with role-based access and electronic signatures

Recipe management with interlocks for spec compliance

Optional MES/ERP handoff for lot genealogy

- CMMC 2.0 Level 2–ready — Controls and historian support CUI protection with role-based access, MFA, encryption in transit/at rest, immutable audit logs, and SIEM export.

When Performance Matters

Partner with CEC – Your Best Source for Aerospace Heat Treating Equipment!