Annealing Furnaces

We Find the Right Furnace for You

CEC Annealing furnaces cover a broad range of Steel and Aluminum applications including tempering, normalizing, and aging, and similar automated loading, unloading and natural or forced cooling is possible with roller hearth, tip-up or batch arrangements. More steel applications can be seen under “related information” below.

The annealing process will soften the raw material, making it more flexible for use in coiling and other applications where flexibility is needed. The actual process of annealing requires that the metal be heated above the transformation point and then left to cool slowly. The exact temperature needed and the time will vary based on the type of metal being used. CEC’s precision furnaces make sure that you get consistent temperatures and times on every batch. As a leader in annealing furnace design, CEC offers the most advanced options in annealing furnaces. CEC has produced annealing furnaces for some of the biggest annealing furnace manufacturers from around the world. To find the right furnace for your annealing job contact one of CEC’s applications engineers.

Industrial Annealing Furnace Options

- Automated loading & unloading

- CEC Axial Blaster Fans

- Self-cleaning cooling coils

- A variety of atmosphere protection features

- Natural or forced cooling

- Continuous Annealing Roller Hearth Furnaces

- Tip-up & Batch arrangements

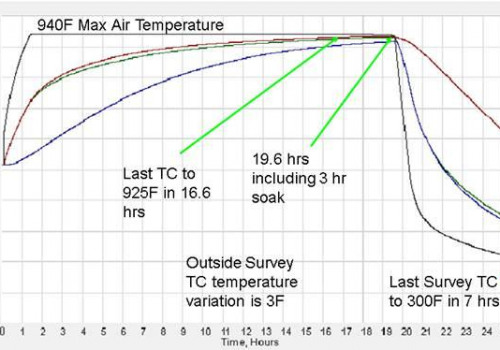

CEC has developed a computer program to predict coil heat up and cooling.

The self-cleaning cooling coils built into CEC annealing furnaces have many benefits.

- Reduction in cooling time since each annealing oven’s internal circulation fan has finned cooling coils built around it that add significant surface area for heat transfer compared to external cooling coils.

- Less connected horsepower due to elimination of external cooling fan that is necessary with external cooling coils.

- No external ducts and no dampers needed as with external coils to close/open the cooling ducts.

- Less floor space requirements due to elimination of external cooling fan, ductwork, and external water cooling coils.

- Less chance for air leaks into the furnace due to elimination of external cooling fans and cooling ducts which can leak due to expansion/contraction at every cycle.

- Less operating horsepower due to shorter cycle time.

- Cooling can be controlled for each zone of control similar to heating control.

- Self-cleaning of cooling coils internals by initial steam generation at start of cooling cycle. For external coils they are cold at the start of the cooling cycle and do not have this automatic internal cleaning.

- Coil surface exposed to heating on the outer surface since inside the annealing oven. This burns out any residue on coil outer surface. External coils get clogged and have to be cleaned due to build-up that reduces the cooling performance.

UNMATCHED PRECISION

CEC’s precision furnaces make sure that you get consistent temperatures and times on every batch.

The Annealing Steel Experts with 58 Years of Experience

For Annealing Steel we offer:

- Normalizing of fabrications

- Tempering

- Roller Hearth Furnaces

- Tip-up Furnaces

- IQ configurations and interface

CEC Aluminum Annealing furnaces are broadly viewed as technology leaders. Whether coil, foil or wire CEC furnace systems integrate ease of loading and unloading, lowered cycle times, integrated self-cleaning cooling and CEC developed and built fans. CEC annealing ovens are heavy-duty and built for 365 X 24 operation.

For more than 58 years CEC has built custom furnaces for many applications including those needed for metal annealing including annealing steel. CEC has an AMCA type fan test center to assure fans flow at a given pressure and horsepower. Fans are Computational Fluid Dynamic(CFD) matched to customer load configurations that allow existing fixtures, cranes, trays, saddles and products to be incorporated into the furnace and support machine(s) interface.

For Aluminum coil, CEC has developed unique self-cleaning cooling coils which are recirculation fan interfaced to allow improved cooling cycle times with little to no cooling coil maintenance. In large coil applications CEC moves the furnace which allows you improved access to the product load area by your overhead cranes.

CEC, an annealing furnace manufacturer, specializes in annealing furnaces designed for industrial steel. CEC carries several furnace types to choose from based on the size of your operation and the temperature and features needed for your job. CEC’s precision manufacturing and decades of knowledge ensure that your annealing oven will get the job done and stand the test of time.

Call us and speak to a CEC applications engineer today; see why companies like Ford, Norsk Hydro, Aleris, Alcoa, Southwire, Alcan, VAW and Encore call on CEC for their Annealing and similar furnace needs. Your success is our reward; we will work hard for you and your company.