Pusher Furnaces Evolved

See what the next generation of pusher furnaces can offer you.

The Best just got Better.

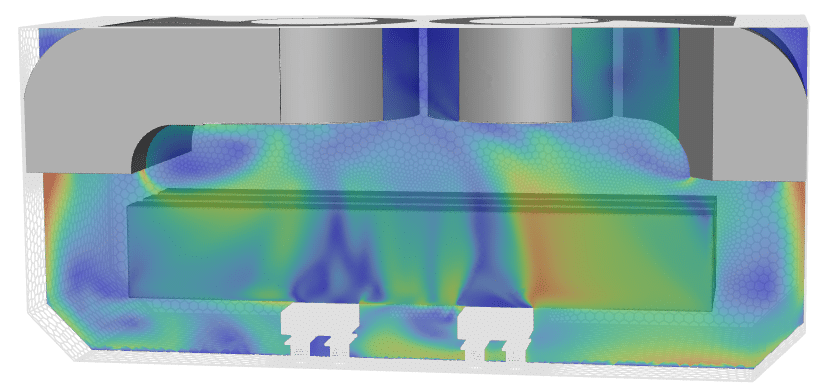

While pusher furnaces are a mainstay in aluminum milling and other industries, their designs have lagged behind the advances of furnace technology. CEC has taken our decades of experience in creating rugged and reliable furnace systems, and added innovative design improvements that bring our pusher furnace systems to the next level. Some of the advantages our cutting-edge systems offer:

- Full seal door technology to massively reduce heat loss

- Energy efficient heating design

- Advanced load tracking and logging

- Automated control and performance tracking

INNOVATION AND EXPERIENCE

CEC engineers bring the best in latest techniques and technologies to the tried and true designs.

Rugged and Reliable

Underneath all of the advantages that CEC’s industry-leading innovations bring, the core of our pusher systems are made with the same meticulous design standards and rugged construction methods that make all CEC systems a durable, reliable, and long-lasting choice for your production needs. There are no compromises when it comes to quality, and CEC will stand behind our systems 100%.

Let us know what you need for your next pusher.