Drop Bottom Heat Treating Equipment

Critical Parts with Tight Specifications? We Can Build the Furnace You Need.

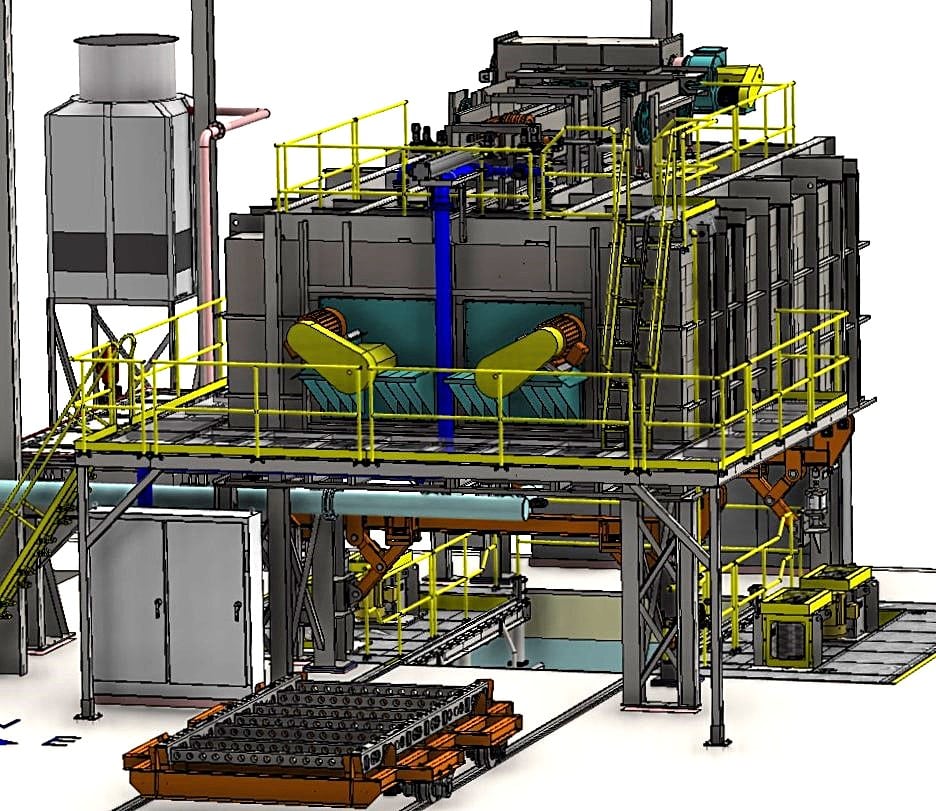

Drop Bottom Furnaces Built for Superior Performance and Reliability

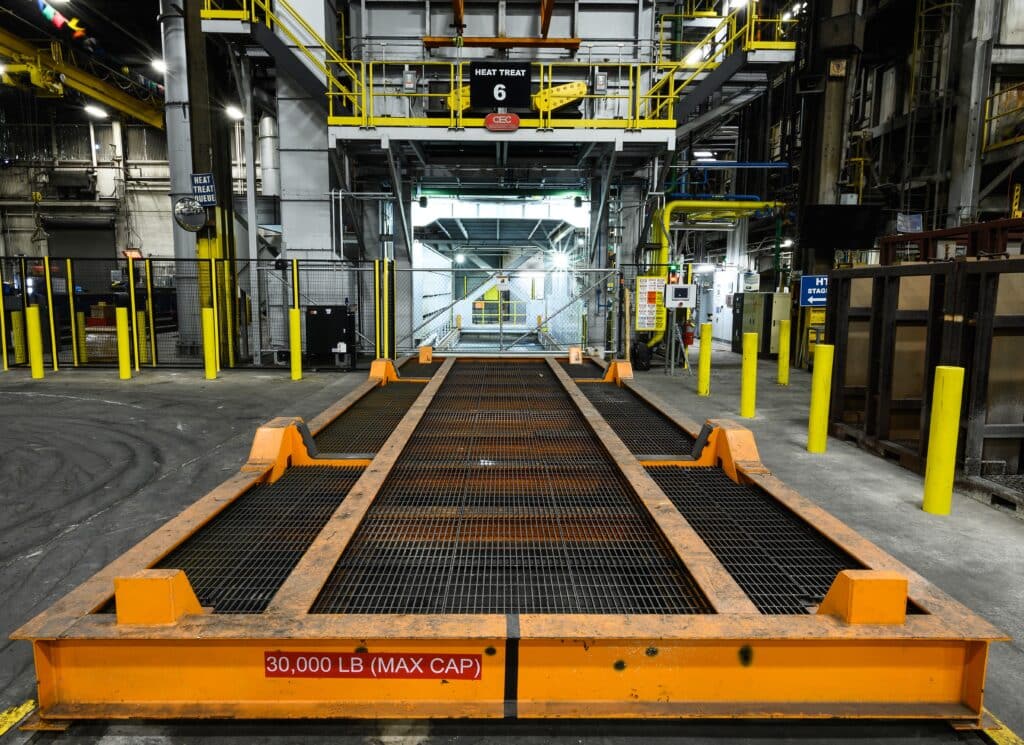

From bolts to rocket body parts, manufacturers across multiple industries rely on CEC Drop Bottom Furnaces to heat and quench their products to stringent standards, such as meeting the Class 1 (± 5°F) requirements of AMS2750.

- Decades of Experience: CEC has crafted effective and efficient treatment solutions for loads of any size, type, and weight.

- Rigorous Engineering Design: Thorough calculations are backed and verified by Computational Fluid Dynamic (CFD) simulations to guarantee superior uniformity.

Whatever the process requirements or product dimensions, let us know what you need your drop bottom furnace to handle, and we will work with you to create the best treatment solution.

State-of-the-Art Drop Bottom Furnaces

- Car Loaded Drop Bottom: Nothing beats a car-loaded drop bottom furnace for simplicity and efficiency. Capable of handling extreme weights, these systems are rugged and dependable.

- Mobile Furnace Drop Bottom: Large and complex loads are easily handled in a mobile furnace drop bottom system. Automated control systems take the guesswork out of recipe times and part movement.

- Mobile Quench Drop Bottom: With no need for a foundation pit or cleared overhead space for a mobile furnace, a mobile quench system can treat your smaller product loads with minimal impact to building design.

- Vertical Drop Bottom: Long parts or extrusions are often difficult to treat, especially if straightness is critical. Vertical drop bottom furnaces are a superior choice for processing such challenging parts.

CEC will work with you to provide the best furnace for your product.