Heat Treating Solutions for Critical Energy Infrastructure

Powering the Energy Industry with Precision Heat Treatment Solutions

Trusted by Energy Industry Leaders

Many of the companies rising to meet the ever-expanding need for energy infrastructure choose the unparalleled performance, efficiency, and reliability of CEC equipment for their heat treating needs.

- Conventional and Nuclear Power: Stress-relief for turbine blades, rotors, and casings; Post-weld heat treatment of pressure vessels

- Transmission and Distribution: Transmission wire annealing; Insulation coating curing; Transformer core stress-relieving

- Oil, Gas, and Geothermal: Pipeline component normalization, quench and temper; Pressure vessel post-weld heat treatment; Valve, flange, and pump component stress-relieving

- Renewable and Grid Storage: Stress-relief for wind turbine blades, casings, and rings; Tempering for generator components

Experience You Can Count On

Since 1959, CEC has partnered with manufacturers in the energy industry to design furnaces that enhance productivity and meet exacting metallurgical standards. Every furnace is backed by CEC’s full lifecycle support – parts, service, everything your system needs to run like new year after year.

Providing the Energy Industry More than Just Exceptional Performance

- Standards-Aligned: Systems expertly designed to meet requirements from your product standards, including ASM, ASME BPVC, NNPP/NR, NADCAP, and CQI-9.

- Throughput and Uptime: Equipment engineered to endure long duty cycles and maximize production without costly downtime.

- Audit-Ready Data: Times, temperatures, events, all the information on your product cycle you need, there when you need it.

- Built with You: Joint design reviews and frequent project updates ensure that the system you receive meets every expectation.

Cutting-Edge Controls and Enhanced Data Integrity

- The Best in Automated Control: With a PWHT multi-PID relational control program, our PLCs hold precise temperature balance and reduce strain on parts with varying section thicknesses throughout the cycle.

- CMMC 2.0 Ready: Both CEC and our furnace systems are meticulously prepared to handle sensitive CUI and FCI data. System and cycle data is gathered, stored, and reported using secure-access immutable information systems.

- Pyrometry Spec Integrated: Calibration, uniformity, and controls testing requirements are scheduled in to the system controller to help you stay on top of your specification compliance.

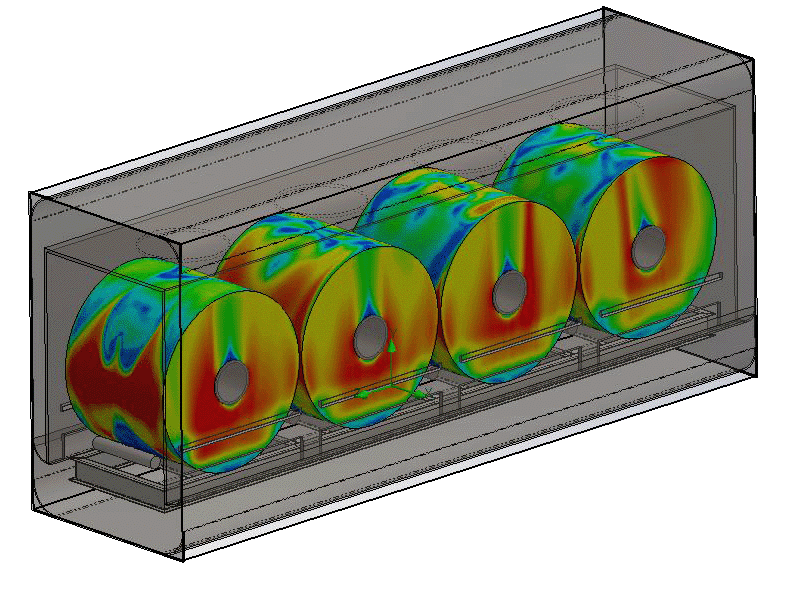

Spotlight: Small Modular Reactor Vessel Post-Weld Heat Treatment

With the rise of Small Modular Reactors comes the difficulty of post-weld heat treating complex reactor and pressure vessels. CEC has designed a PWHT system capable of keeping the temperature across the vessel precisely balanced during the heating and cooling cycles, minimizing stress in variable-thickness vessels.

The CEC PWHT system uses advanced relational geometric mapping of the vessel-mounted control sensors to establish a control ratio network with the heating elements, enabling each sensor to act as a control zone no matter where it is located. PID control for each zone is processed by the control network to apply heat exactly where it is needed, virtually eliminating hot and cold spots on the vessel.

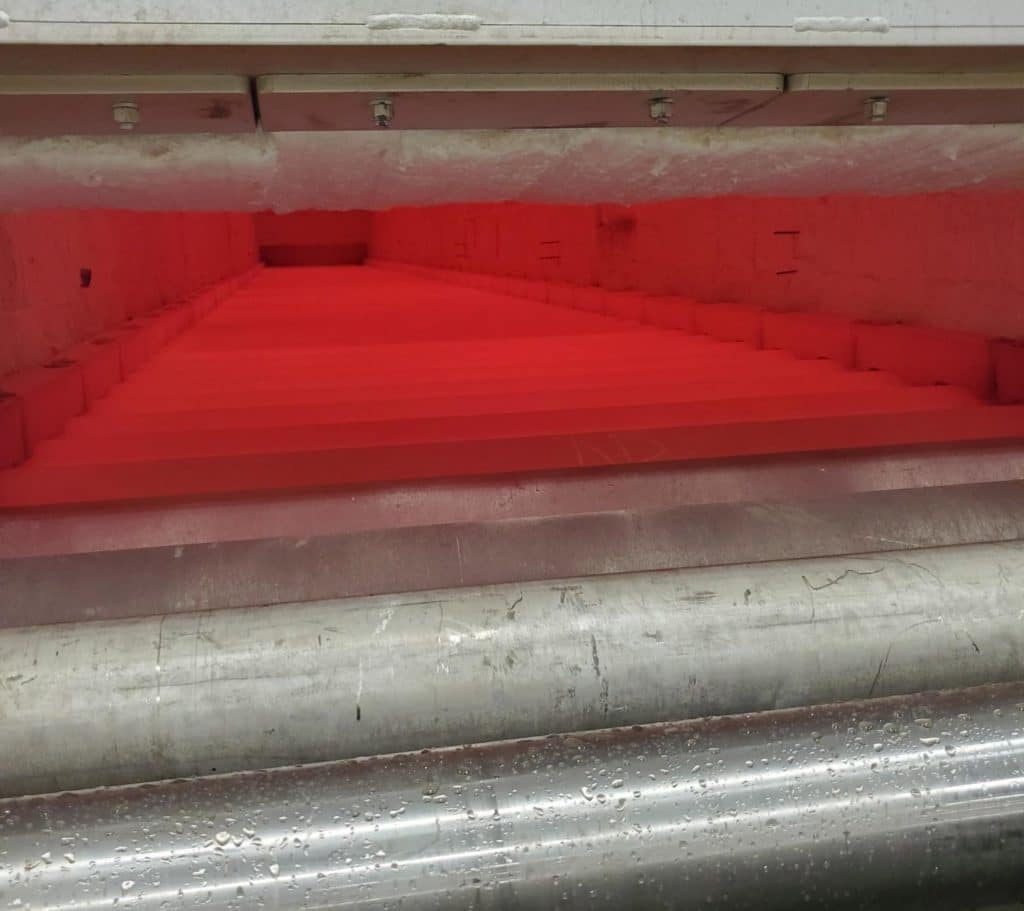

Spotlight: Power Transmission Wire Annealing

In the power transmission industry, wire annealing is essential for achieving the proper balance of conductivity and flexibility in finished cable. To meet today’s growing infrastructure demand, production efficiency and throughput are critical.

CEC’s mobile annealing furnaces are built with continuous production in mind. Each furnace features two independent load pads—while one pad is actively annealing, the other can be simultaneously unloaded and reloaded. This alternating setup virtually eliminates idle time between cycles, allowing for near-continuous operation and significantly higher production rates.