Titanium Heat Treatment

Titanium

CEC Furnaces for Titanium cover a broad group of heat treatment disciplines, including

- Slab or bar Pre-heat for Rolling mill

- Solution Heat Treatment

- Age hardening

- Annealing

- Forging preheat Furnaces

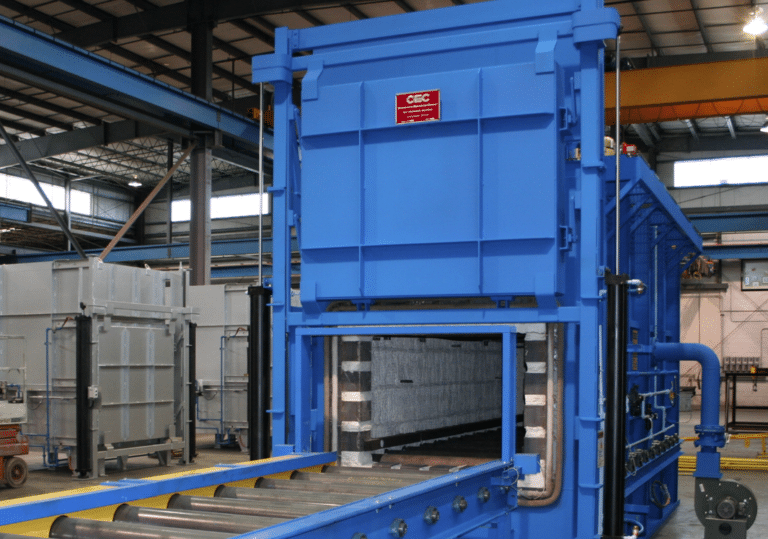

CEC has experience in many types of these furnaces. Our ability to automate these furnaces for loading and unloading will aid in greater productivity or quality for your manufacturing facility.

CEC can rapidly move plate or billet from the furnace to rolling or forging mills to conserve heat loss. Table drives or driven conveyor sections interface with the furnace, mill, or load or unload conveyors. Programmed variable frequency gearbox drive acceleration is confirmed with encoders. The PLC coordinates and confirms modern machinery system designs.

Browse Our Offerings

Quenching Options

These furnaces can be fitted with a variety of quenching options including:

- % synthetics to water automatically controlled

- Spray quench either direct or progressive

- Air and water mix

- Gantry or mechanical manipulators up to 50,000 lbs

Processes will need to be confirmed and logged to meet Nadcap (National Aerospace and Defense Contractors Accreditation Program) requirements. CEC can help to gather and confirm work processing data.

If you are loading and retrieving Titanium blooms for forging, CEC engineers will work with you to automate this process. If fork-trucks are used with heavy blooms then CEC will assure that rugged bumpers, alloy piers, and refractories are applied.

Gantry furnaces or cranes allow CEC to move the furnace or the product load fixture to allow smooth automation for loading or quenching.

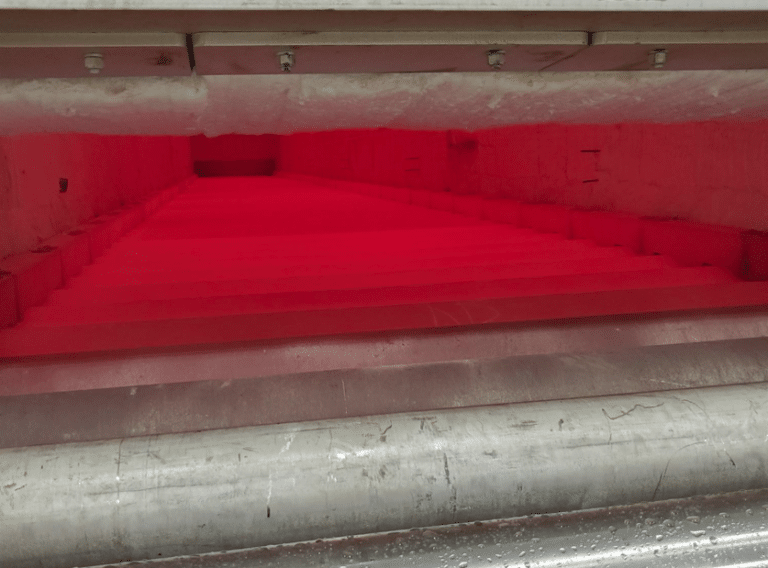

Titanium cast or wrought items can be conveyed by roller hearth furnaces, bogie hearth (hot or cold cars), or protective atmosphere drop bottom furnace. Tip-Up furnaces or Pit type batch furnaces can be used for processing large Titanium castings or forgings. A big challenge for each of these furnace types is getting the part into the quench rapidly. Gantry furnaces can allow large parts to be moved quickly into quench tanks or on to further processing.

These furnaces can be fitted with a variety of quenching options including:

- %synthetic to water automatically controlled

- Spray quench either direct or progressive

- Air and water mix

- Atmosphere covered quench

- Gantry or mechanical manipulators up to 50,000 lbs

Valuable Titanium parts need excellent control for quench timing, temperature uniformity, and atmosphere assurance. CEC can offer sophisticated control systems that can document the production mentioned above parameters

Please call CEC today and see if you agree that we are “innovative to the core”. We aim to make innovation pay off for you in all your heat processing applications. We seek to lower: pollution, energy usage, floor space, WIP, and employee risk while improving product repeatability.

Our staff has hundreds of years of furnace manufacturing experience that can make your manufacturing processes for Titanium more reliable and at a higher confirmed quality.