Automotive Heat Treating Solutions

CEC machines process over 70,000,000 Head, Block and Wheel castings every year.

Automotive Heat Treating Systems for T4-T7 Aluminum

For more than 65 years, CEC has delivered custom automotive heat-treat systems engineered for uniformity, throughput, and distortion control that integrates cleanly with your upstream and downstream material handling.

- Uniformity you can trust. Tight control of soak/age zones, fan curves, and load mapping for spec-conforming results.

- Recipe governance that prevents mistakes. Part/Alloy IDs, interlocks, and e-signoffs block wrong-temp or wrong-time runs.

- Built for HPDC reality. Fixtures, transfer, and quench tuned for thin-wall structural castings and mixed section thicknesses.

- Audit-ready from day one. CQI-9 artifacts, SAT/TUS scheduling, and calibrated instrumentation—ready for PPAP.

Please call us and see how one of our senior applications engineers can guide you through a design and installation process to meet your critical manufacturing needs.

Knowledge & Expertise through Engineering Excellence

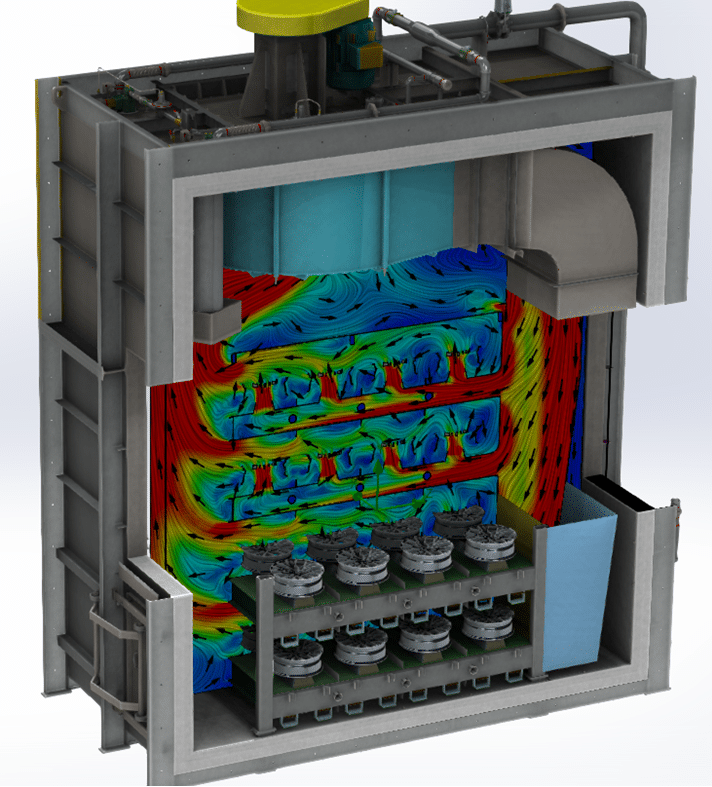

From alloy curves to quench maps, CEC converts testing into production wins. Our library of 6,000+ in-house trials and extensive CFD simulations helps you reach properties sooner, stabilize UPH, and walk into audits with confidence.

- Data, not folklore. Time-at-temperature and transfer windows derived from 6,000+ real parts—not spreadsheet theory.

- Properties on target. Recipes tuned to achieve specified mechanical properties for common automotive alloys.

- Audit-ready methods. Documentation, SAT/TUS scheduling, and calibration practices aligned to CQI-9/AMS2750 expectations.

- Application depth. Engine blocks, heads, transmission housings, chassis, EV battery trays, motor housings, inverter coolers, wheels, and more.

- Customer involvement during design reviews to align with engineering, operator, and maintenance team’s requirements.

AUTOMOTIVE PART HEAT TREATMENT EXPERTS

Our staff has decades of experience in applying, designing, fabricating, installing and servicing thermal processing equipment.

CEC has tremendous knowledge as the world leader in air quenching, water quenching and spray quenching. Our testing has been refined over the years to show the expected physical property differences and determinants.

CEC is the originator of trayless, basketless T6 and T4 heat treatment systems for cored castings; this technology has been adapted to non-cored casting and forgings. No furnace company in the world has more experience is this area than CEC.

Please call and see how we can help with thermal processing and material handling needs. Our experience with Mercedes, BMW, Norsk Hydro, Alcoa, Ford, GM, Nemak, Teksid and other fine companies should give us insight into your application. Our in-house simulations and testing may be just what you need to make your automotive parts more economically and at a higher quality.

CEC can also operate your system for you and allow you to pay for the system on a cost per casting or forging basis. CEC has operated systems under contract in USA, Germany and Mexico for our customers. Contact one of our Sales Engineers to discuss.

Heat Treating Equipment for Automotive Parts

CEC has many types of Automotive application furnaces including:

- Chain type wheel furnaces for T6 and T4

- Horizontal heat treatment furnaces for extrusions or wrought products

- IQ furnaces

- Mesh Belt furnaces for small parts

- Hardening and tempering continuous furnaces

- Drop Bottom furnaces

- In-Out furnaces

- Conventional T6, T4 and T5 furnaces for Solution Heat Treatment

- Roller Hearth furnaces of all types

- Car Bottom, Bogie Hearth or Mobile furnaces