Car and Mobile Heat Treating Equipment

Superior Car Bottom and Mobile Furnaces to Fit Your Product and Process

CEC engineers hot-car, cold-car, and mobile (traveling-shell) furnaces to match your material flow. For overhead-handled load (wire spools, large forgings, or aluminum logs) a mobile furnace keeps the work stationary, reduces bay length, and cuts handling time. Where car-bottoms are preferred, we provide matched car-pullers for hot and cold cars or integrate with your existing equipment. Systems can be fully automated and interlocked to interface with rolling mills, forges, and downstream handling.

Innovative Design for Maximized Hot Car Performance

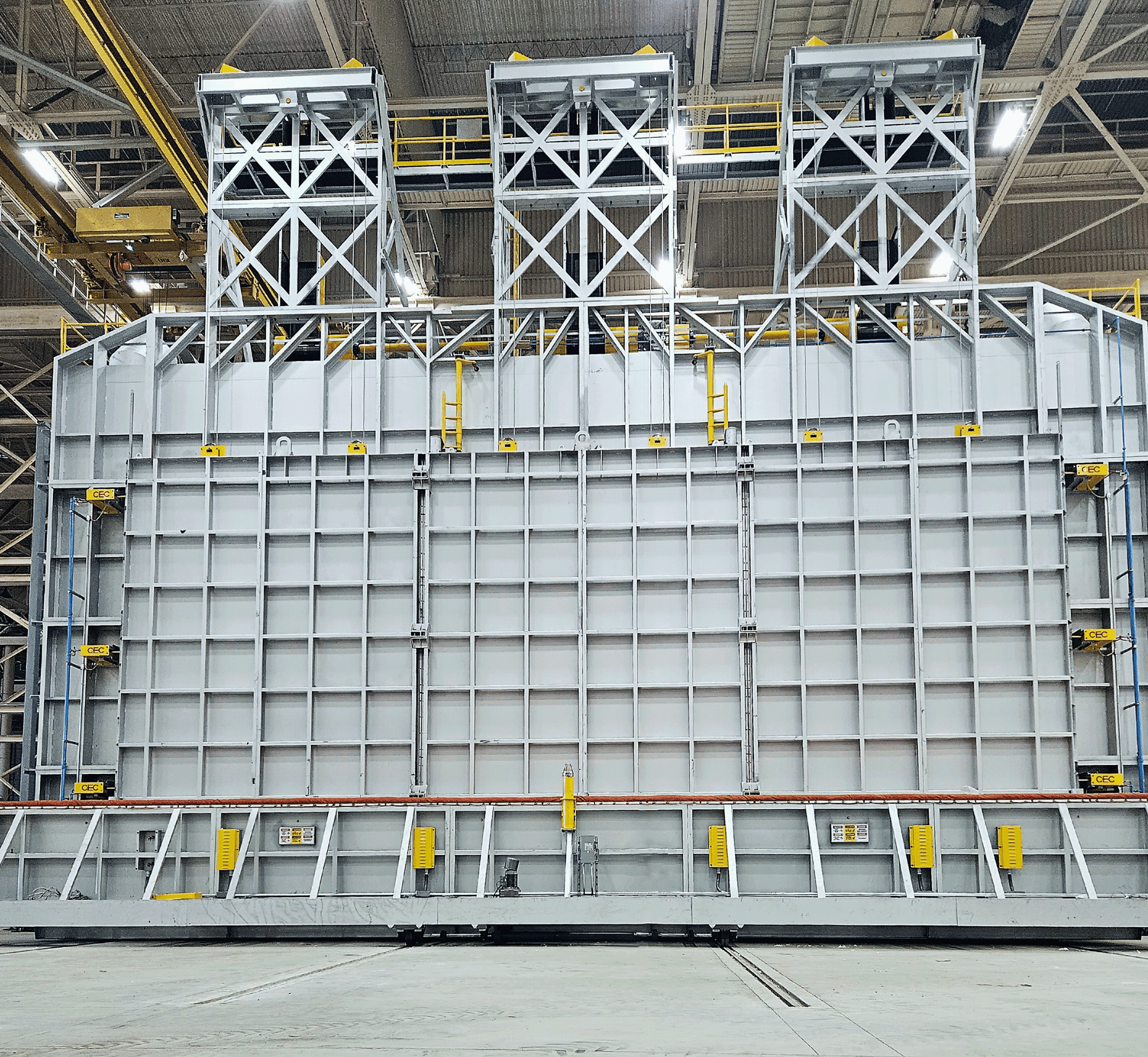

Car bottom furnaces employ a manually or automatically operated car to take large loads in and out of the furnace. The car bottom functions as the floor for the furnace making these furnaces particularly good for large loads that need to be heat treated. CEC’s innovative designs ensure that the car seals perfectly with the rest of the furnace, minimizing leaks in atmosphere and losses of energy.

Our state of the art dry lubricant Hot Car wheels will offer minimal friction to reduce stresses caused by pulling loaded Hot Cars. Hot Cars are normally used when the customers product requires a protective atmosphere, such as aluminum coil or foil annealing.

OUR MOBILE FURNACES HAVE SERVED THE HEAVY INDUSTRIAL STEEL AND ALUMINUM MILL INDUSTRIES FOR DECADES

Car Bottom or Mobile furnaces are used for many heavy industrial steel and aluminum mill applications, such as:

- Aluminum homogenizing of log, billet or plate

- Aluminum sheet, coil or foil annealing

- Aluminum plate homogenizing

- Aluminum reheat or preheat (prior to rolling)

- Large steel or aluminum castings

- Forging heat treatment

- Wire annealing

- Forging preheater

Unique Know-How for Better Furnace Systems

CEC car bottom and mobile furnaces often employ some of CEC’s unique know-how and components, including:

- CEC no-vibration high temperature alloy fans

- Self-cleaning load cooling coils

- Sure seal car designs that minimize energy and atmosphere leaks

- Control systems to Level I, II or III to fit your quality and inventory needs

- Automated loading and unloading

- Automated interface with your rolling mill or forge

- Pulse or proportional combustion, direct or indirect fired

- Alloy radiant tube construction, with or without recuperation

Things to consider when looking at a car bottom furnace for your facility include materials that will be placed in the furnace, the temperatures needed, heating and cooling times required and the amount of space in your facility. Depending on the materials to be heated, temperatures and heating and cooling times can vary as different metals require different processes. The amount of space available will also factor into the size of the car bottom furnace. If there is not enough space available another type of furnace may be better.

Call CEC today and talk with one of our experts about your mobile furnace or car bottom type heat treatment furnace today. We can often advise and predict both theoretically and empirically your cycle times and product temperature uniformity. See why Alcoa, Southwire, Alcan, Aleris, Union Tank Car and many other fine companies trust CEC with their mobile furnace needs.